As 40G and 100G have been applied in data centers to satisfy the demands of massive data transmission, high-density cabling system has become a common phenomenon. Solutions characterized by quick installation are preferred since they can save time and money. Pre-terminated cabling system has come into data center managers’ sight in recent years, because it can provide quick, plug-and-play network deployment for structure cabling. Then, what is pre-terminated cabling system in essence? And what we can expect from this cabling alternative? The information about pre-terminated cabling system will be fully covered in this article.

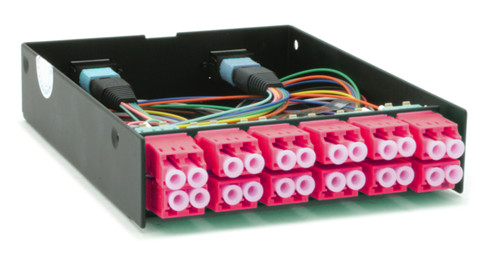

Pre-terminated cabling system refers to factory manufactured cables and modular components with connectors already attached. Usually those cables and modular components have been tested, qualified and are ready to plug and play in network deployment. In addition, they are available in both fiber and copper cabling. Pre-terminated cabling system simplifies the installation of network devices by providing high-density and plug-and-play solution. Pre-terminated assemblies come in various forms, such as MTP trunk cable, MTP fanout cable or MTP breakout cable, MTP fiber optic cassette and pre-terminated cable bundles with protective pulling grips installed over the connectors at one end (shown as the following figure).

Pre-terminated cabling system can bring a raft of advantages to cable installers and end-users.

The high speed deployment offered by pre-terminated cabling system is an equally important feature which helps to save time in various ways. The quick plug-in connections of network devices allow fiber and copper links to be installed in significantly less time than traditional field-terminated links. In addition, since the assemblies are factory terminated, the transmission testing is performed by the manufacturer before shipment. This greatly saves testing and troubleshooting time. Also, pre-terminated assemblies are factory terminated which reduce many of the problems that may occur with field terminations.

For data centers, the available space for high-density cabling is always precious. Components that contributes to promoting space utilization will gain popularity among data center managers. With massive cables being adopted in the data centers to carry out data transmission, pre-terminated assemblies offer cabling with much higher density and flexibility for data center upgrades.

With pre-terminated assemblies, you don’t need as many on-site engineers pulling cables in and terminating them. As the pre-terminated links have been pre-tested, this vastly mitigates the need for troubleshooting and retesting.

It is necessary to pay attention to heating and cooling issues in high-density cabling environment. Pre-terminated cabling system allows much more flexibility in configuration for installers working in compact space. It is also able to optimize airflow by using pre-terminated assemblies such as MTP trunk cable and MPO cassette, in conjunction with high density frames.

Pre-terminated cabling system is commonly used in two fields: data center and open office. In response to the accelerated network capacity and application processing demands, data centers are expanding dramatically both in number and size. Pre-terminated cabling system provides an ideal plug-and-play solution for links between switches, servers, patch panels, and zone distribution areas in the data center. The open office also benefits from the pre-terminated cabling system which can be quickly reconfigured to match the moves, adds and changes. Pre-terminated cabling system offers unsurpassed advantages over conventional field installed system, which partially explains why the use of factory pre-terminated assemblies continues to grow, especially for data centers.

With several advantages of time saving, space saving, labor saving and cooling, pre-terminated cabling system provides an increasingly popular way of delivering a project in a more timely and cost effective manner. If your data center or network application needs speed and testing simplified installation, pre-termination cabling system is an ideal choice.